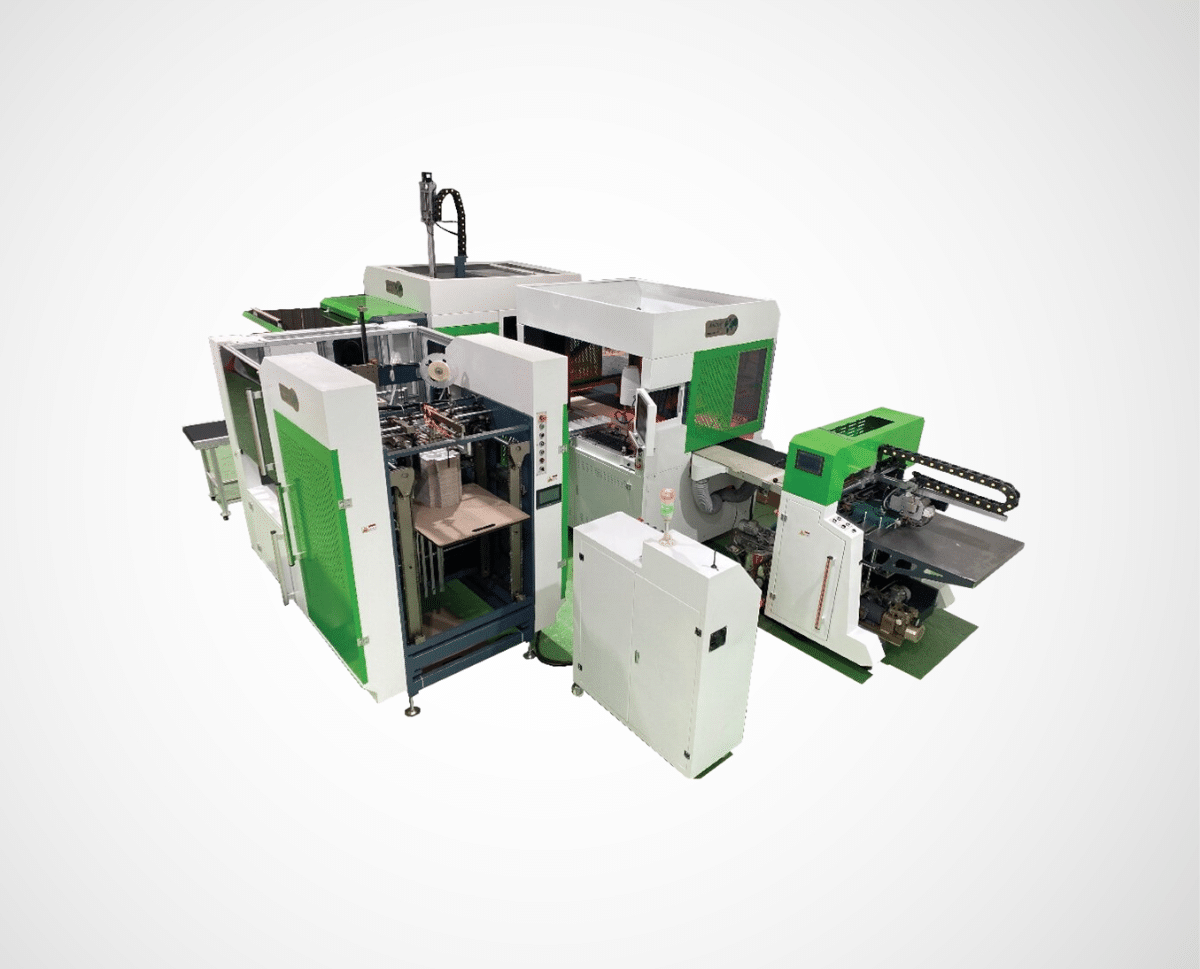

Introducing the Avenir BOXMATIC iSet Smart – the pinnacle of automatic rigid box fabricating solutions. With a focus on precision and efficiency, this state-of-the-art system boasts a futuristic box covering material management system, featuring fully automated feeders and high-precision servo-driven animal glue application for unparalleled consistency. The system's robotic box positioning, powered by a 4th generation Yamaha robot, offers remarkable accuracy, handling weights up to 10kg, and its smart iSet operating function simplifies size changes with a touch-screen panel. The result? Seamless production of high-quality luxury boxes with ease, efficiency, and unwavering precision.

Experience the future of box fabrication with the Avenir BOXMATIC iSet Smart. From intelligent glue application and advanced thermal taping to a smart robotic box placement system, this innovation sets a new standard in box manufacturing. The iSet software, designed by European experts, streamlines size changes, while the system can automatically correct box height and dwell pressing time. With a remote control option for troubleshooting and the ability to store and recall various job sizes, this user-friendly solution ensures top-notch box quality and operator convenience. Elevate your box fabrication process with the Avenir BOXMATIC iSet Smart for unparalleled efficiency and precision.

Discover more about this product

Download Brochure

| Technical Specification | |

|---|---|

| Max Box size range | 45cm X35cm x10cm (LXWXH)* |

| 45cm X25cm x15cm (LXWXH)* | |

| Min Box size range | 10cm X 6cm x 2cm (LXWXH) |

| Covering material - Maximum | 60 x 80 cm |

| Covering material -Minimum | 9.5 x 18 cm |

| Covering material weight | 130 – 180 gsm |

| Board Thickness | max upto 3mm |

| Covering material pile feeder height | 40 cm |

| Board material pile feeder height | 100cm |

| Tapes spool dia | 25 cm |

| Cycle speed | 20 cycles/min |

| Machine foot print | 7200mm x 4000mm x 3400mm |

| Power | 13 kw |

| Weight | 4 Tons |

| Air requirement | 5 - 7 bars (70 L/min. 0.6Mpa (air compressor of +/ -2.5 kWs) |

You must be logged in to post a comment.