How do our Rewinder & Slitter

Meet your customers and market needs?

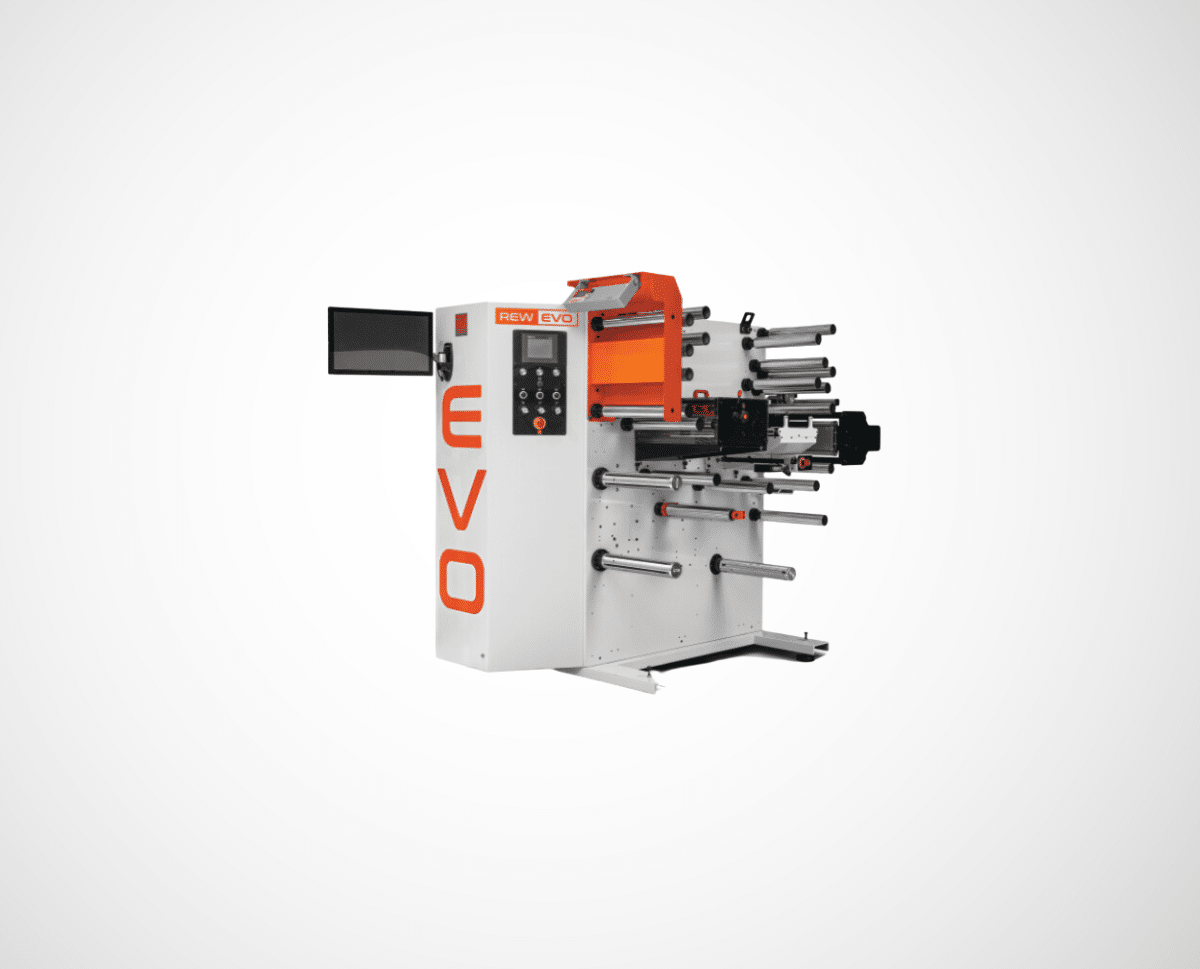

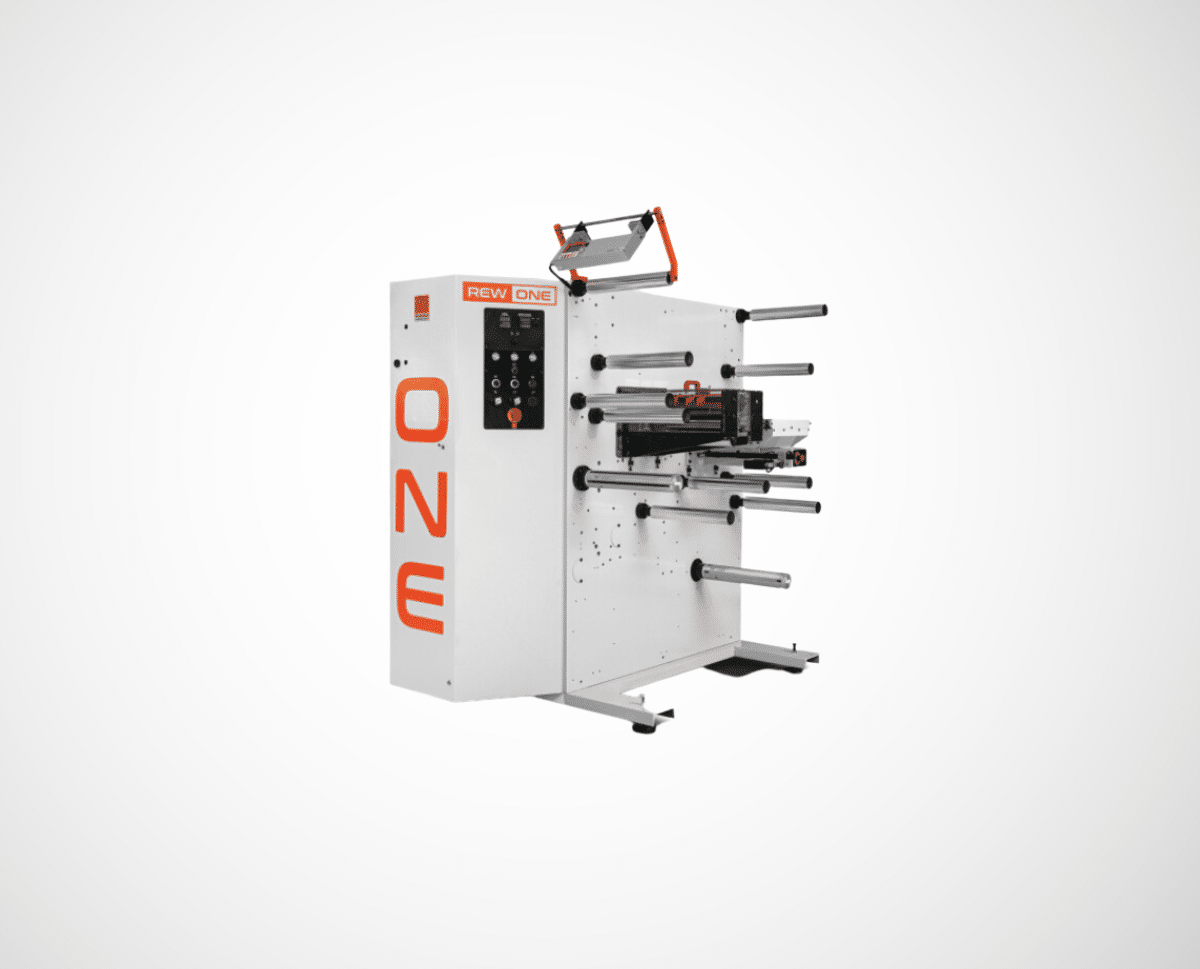

Our rewinder and slitter solutions at Flexo Label Solutions are meticulously crafted to cater to the evolving needs of our customers and the dynamic market. Designed for both small-label printers and large-scale packaging companies, our equipment offers unmatched efficiency and precision in label production.

Efficiency is paramount, as our equipment is optimized to minimize downtime and maximize productivity. With cutting-edge technology and innovative features, we ensure your label production runs smoothly, even with demanding schedules.

Precision is our top priority, delivering consistent and precise results, regardless of intricate designs or challenging substrates.

Versatility is key in a competitive market, and our equipment adapts seamlessly to various label materials, sizes, and finishing options.

Reliability is the foundation of our products, providing consistent performance over the long term with minimal maintenance requirements.

Customer satisfaction is our ultimate goal, offering comprehensive support from installation and training to ongoing maintenance and technical assistance.

Download Brochure

Explore our product categories in detail by downloading our brochures.

Download Brochure

Let's help you!

Our team of technical experts is prepared to provide consultation and support

Our Solutions

Industry Benefits

Rewinder and slitter machines increase production efficiency by rapidly converting large rolls of material into smaller, finished rolls or sheets. This streamlined process reduces manual labor and speeds up production, saving time and resources.

These machines offer high levels of precision and consistency in cutting and rewinding processes. This is particularly important in industries like label printing, where precise dimensions and alignment are critical for product quality and aesthetics.

Rewinders and slitters minimize material waste by efficiently utilizing raw materials. They can be programmed to optimize the use of the material, reducing the amount of unused or scrap material generated during the manufacturing process.

These machines are highly adaptable and can handle a wide range of materials, including different types of paper, film, and other substrates. This versatility allows manufacturers to produce a diverse range of products to meet varying customer demands.

Increased efficiency, reduced waste, and minimized labor requirements result in cost savings for manufacturers. The initial investment in rewinder and slitter equipment is often justified by long-term cost reductions.

Rewinder and slitter machines ensure that each product roll or sheet maintains consistent quality and appearance. This is essential for industries such as food packaging and pharmaceuticals, where product safety and presentation are critical.

The high-speed capabilities of these machines enable faster turnaround times for production, which is especially beneficial in industries with tight deadlines or high demand seasons.

Many rewinder and slitter machines can be customized to meet specific production requirements, allowing manufacturers to tailor their processes to unique customer needs.

Staying competitive in the market often requires the ability to adapt quickly to changing customer preferences and market trends. Rewinder and slitter machines enable manufacturers to respond swiftly to new demands and product variations.

These machines reduce the need for manual cutting and rewinding, which not only saves on labor costs but also decreases the risk of errors and injuries associated with manual handling.

As businesses grow, they can scale their production capabilities by adding additional or larger rewinder and slitter equipment, making it easier to meet increased demand.

You must be logged in to post a comment.