How do our Thermal Laminating Solution

Meet your customers and market needs?

Our Thermal Lamination Solutions are meticulously designed to cater to the diverse requirements of our customers and effectively address the dynamic demands of the market. Equipped with cutting-edge technology and an innovative approach, we deliver efficient and customizable solutions for thermal lamination.

Our thermal lamination machines incorporate advanced features that streamline the entire lamination process, ensuring high-speed and precise lamination. Whether it's enhancing durability, adding a glossy finish, or protecting printed materials, our solutions seamlessly integrate into your production workflow, delivering optimal performance.

We recognize that every customer has unique preferences and specifications. Therefore, our thermal lamination solutions are highly adaptable, accommodating a wide range of materials, sizes, and thicknesses. Whether you require standard lamination or bespoke dimensions, our machines are engineered to meet your exact needs, empowering you to satisfy your clients' diverse requirements.

In today's competitive marketplace, efficiency is paramount. Our thermal lamination solutions are specifically engineered to boost productivity, minimize downtime, and maximize output. By automating processes and reducing reliance on manual labor, we help you enhance operational efficiency, strengthen your capabilities, and maintain a competitive edge.

Furthermore, quality and precision are at the heart of our thermal lamination solutions. We leverage state-of-the-art technology to ensure flawless lamination, delivering impeccably finished products that adhere to the highest industry standards. Our commitment to quality assurance ensures customer satisfaction and enables you to uphold a reputation for excellence.

At AFRA, we prioritize our customers' success and are committed to providing comprehensive support throughout your thermal lamination journey. Our team of experts offers technical assistance, training, and ongoing maintenance services to ensure seamless operations and optimize the performance of our thermal lamination solutions.

Experience the innovation and efficiency of our Thermal Lamination Solutions, tailored to meet your evolving business needs and empower you to elevate your production capabilities.

Download Brochure

Explore our product categories in detail by downloading our brochures.

Download Brochure

Let's help you!

Our team of technical experts is prepared to provide consultation and support

Our Solutions

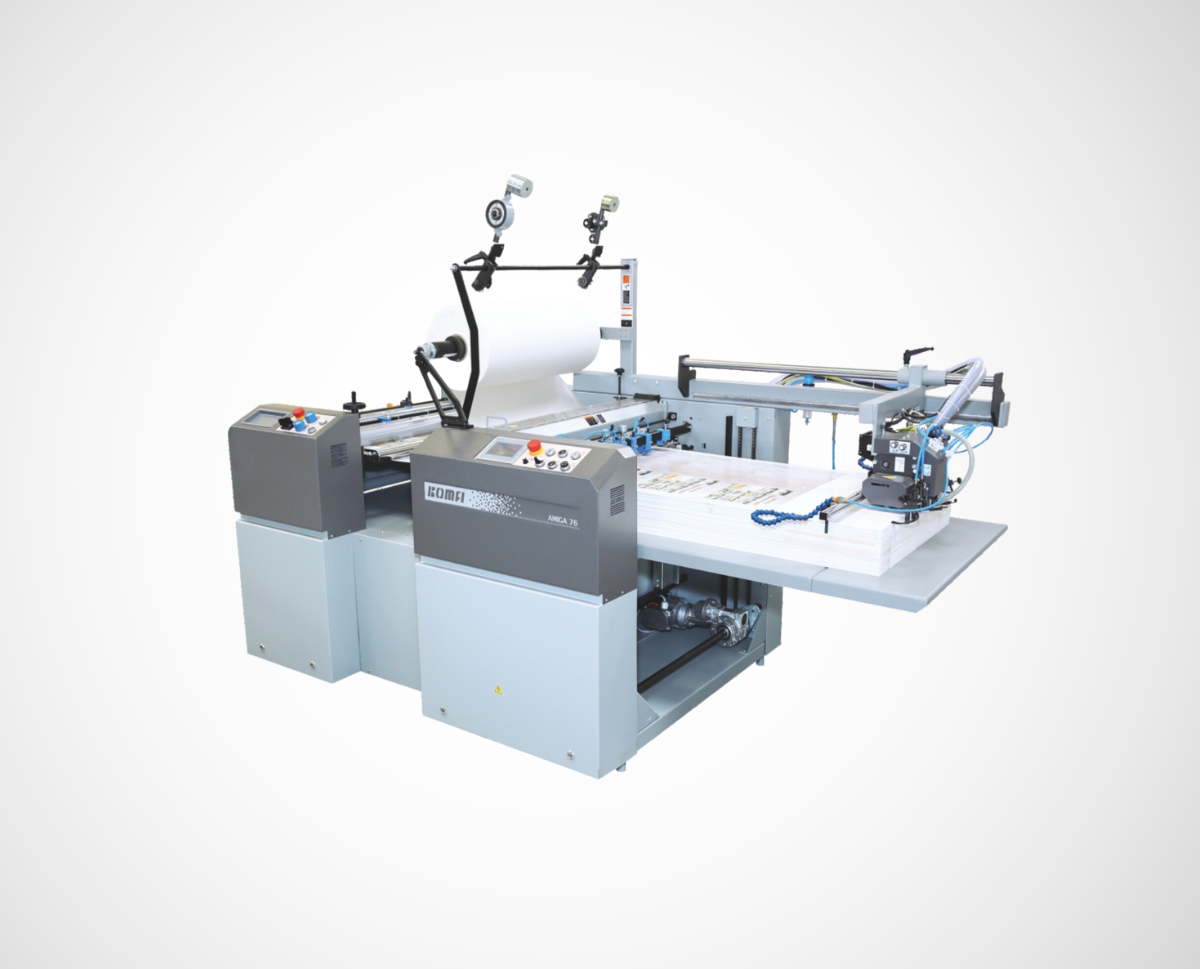

Komfi Amiga 76

Introducing the Komfi Amiga 76 Automatic Thermal Laminator - a state-of-the-art hardware and software..

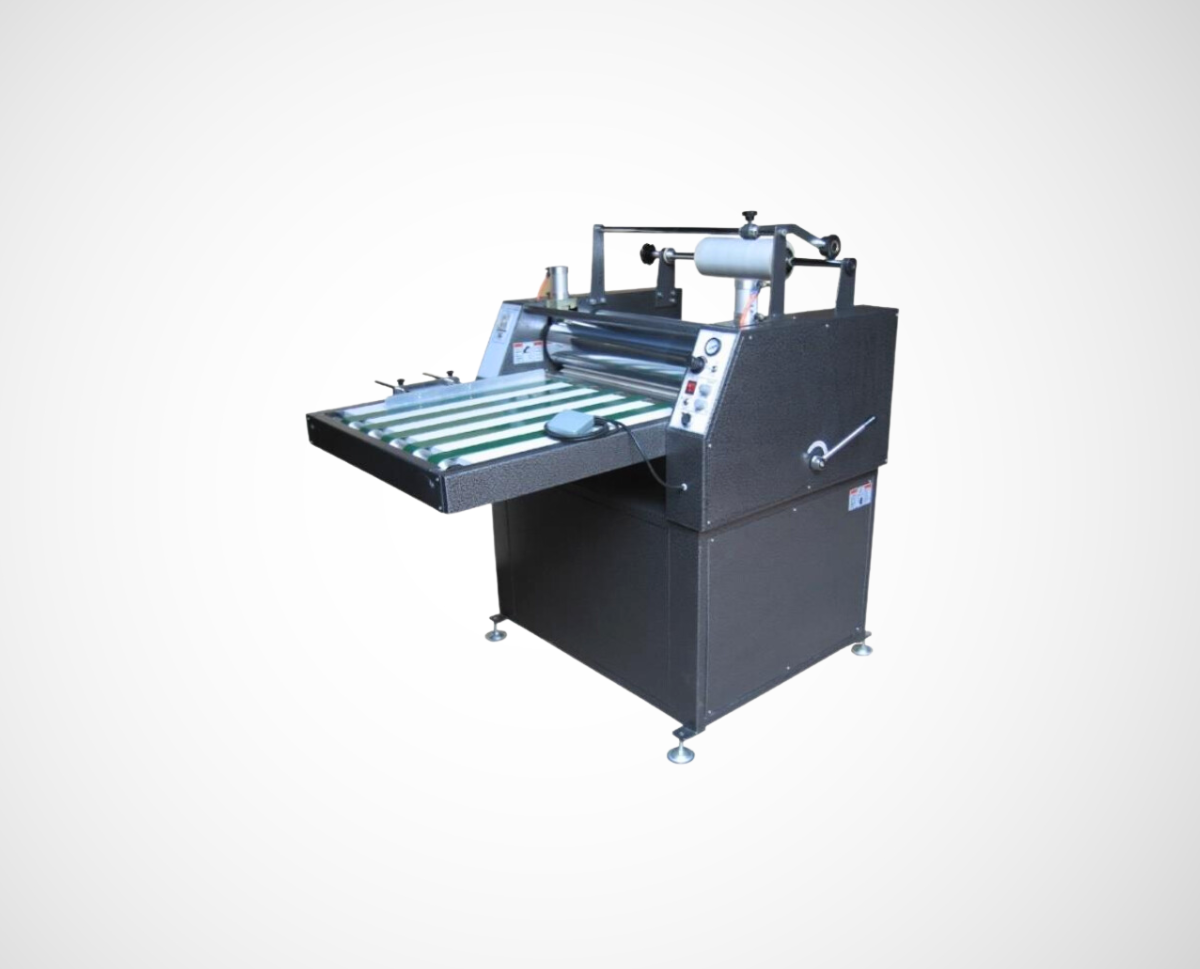

Champion CTL 680/720/900

The CHAMPION CTL 680 Thermal Laminator is a versatile and highly efficient machine designed to safeguard..

Champion CTL HYD 520

Introducing the Champion CTL-HYD 520 Semi-Automatic Thermal Laminator..

Champion CTL HYD 740

Introducing the Champion CTL-HYD 740 Semi-Automatic Thermal Laminator..

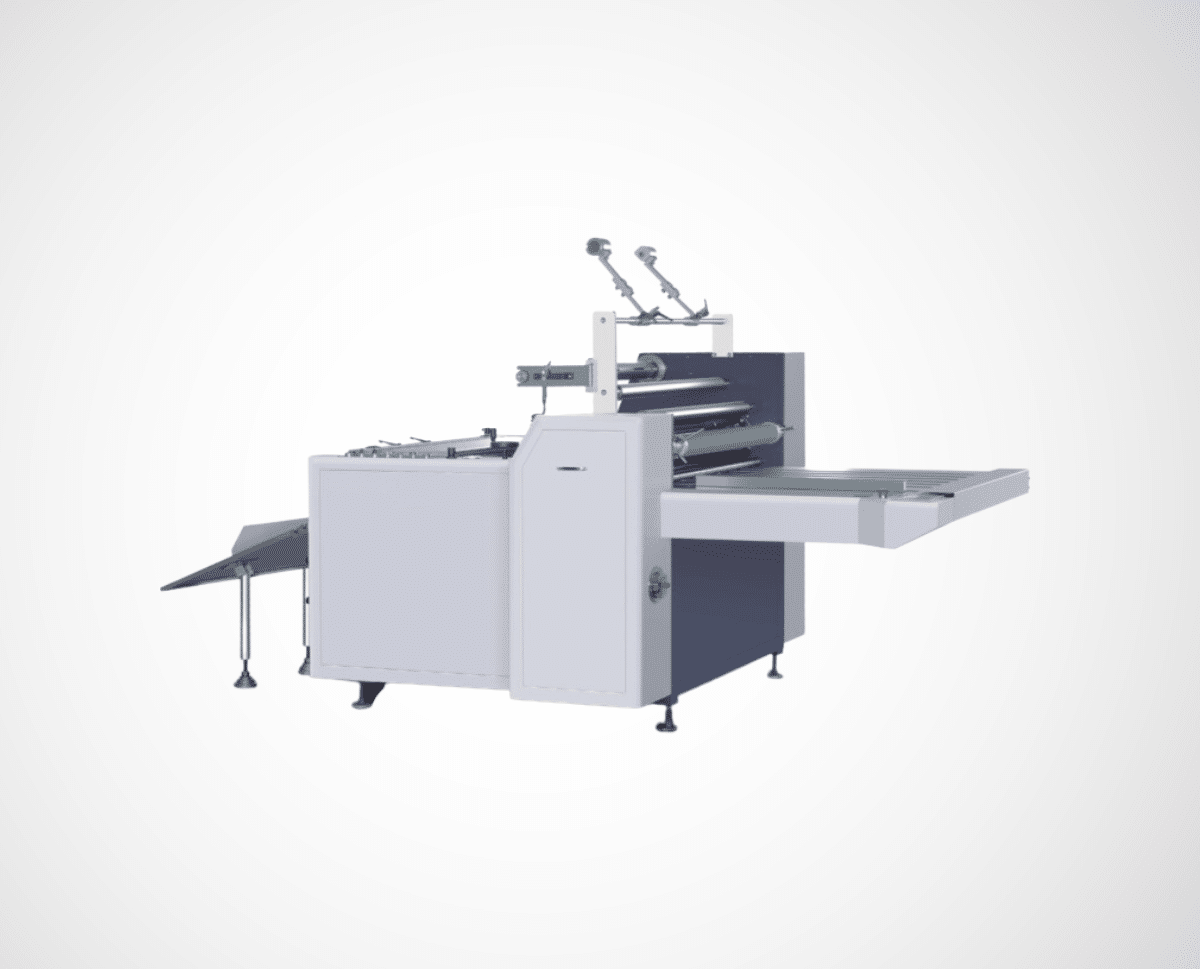

Komfi Delta 52

The Komfi Delta 52 is an advanced automatic thermal laminating machine with features for precision..

Komfi Sagitta 76

Introducing the KOMFI SAGITTA 76 Automatic Thermal Laminating Machine - a robust and durable solution..

Industry Benefits

By automating various processes involved in envelope production, such as cutting, folding, and sealing, our solutions significantly increase productivity. With higher processing speeds and reduced manual intervention, more envelopes can be produced within a given timeframe, resulting in improved output and faster turnaround times

Envelope Converting Solutions streamline the production workflow by eliminating bottlenecks and optimizing resource utilization. Automation reduces errors and rework, leading to higher overall efficiency. By minimizing wastage and maximizing the utilization of materials, our solutions help minimize costs and improve profitability

Our envelope-converting machines offer versatility and adaptability to meet diverse customer requirements. From standard envelope sizes to custom dimensions, our solutions can be easily adjusted to accommodate specific needs. This flexibility enables our customers to cater to a wide range of market demands, expanding their business opportunities.

Envelope Converting Solutions employ advanced technology and precision mechanisms to ensure accurate cutting, folding, and sealing. The result is high-quality envelopes with consistent dimensions and professional finishing. By maintaining strict quality standards, our solutions help enhance the reputation of our customers and foster customer satisfaction.

Our solutions are designed to minimize downtime by incorporating features such as automated changeovers and quick setup processes. This reduces the time required for machine adjustments between different envelope sizes or types, allowing for seamless transitions and uninterrupted production

We provide comprehensive technical support and expertise to our customers. Our team of professionals offers training, maintenance services, and troubleshooting assistance, ensuring smooth operations and minimizing disruptions. This support maximizes the uptime of our envelope-converting solutions and helps our customers optimize their production processes.

You must be logged in to post a comment.