- Home

- Packaging Finishing Solutions

- Corrugated Carton Solutions

Corrugated Carton Solutions

Corrugated Paperboard Production Lines

AFRA Printechnik delivers advanced corrugated paperboard production solutions designed to meet the demands of modern packaging manufacturers. Our machines deliver exceptional precision, durability, and efficiency, ensuring high-speed production of 2-ply, 3-ply, and 5-ply corrugated paperboard with minimal waste.

Our Solutions

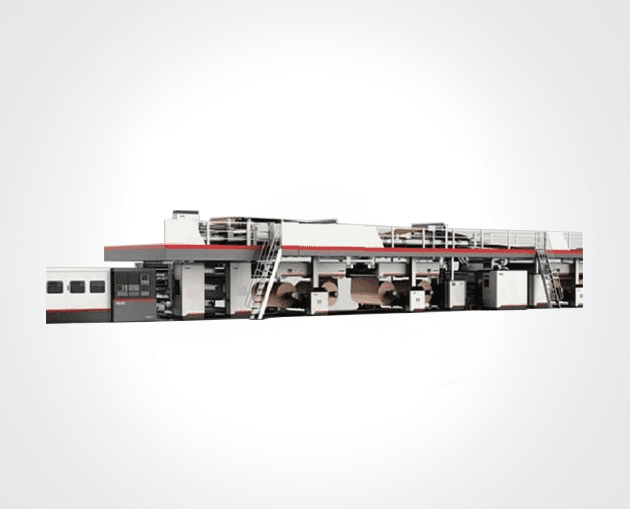

CHAMPION CARTOPRO

CARTOPRO-1800-5PLY – high-speed 5-ply corrugated cardboard line, achieving 150–300 m/min to meet diverse production needs.

CHAMPION CARTOCASE

High-speed 4- or 5- color Flexo printer slotter and die cutter for seamless printing and precise box making. Fully configurable lines include printing, folder gluing, and inline strapping to meet your production needs.

CHAMPION CARTOCUT

CARTOCUT ECO 1650-3S – precision die cutting machine with lead-edge feeding and stripping for efficient, high-speed performance. Available in multiple sizes to suit your production requirements.

CHAMPION CARTOFOLD 1100

High-speed folder gluer with automatic feeding, gluing, folding, and counting. Delivers up to 220 cartons per minute with precise, reliable, and efficient performance

Advantages of Custom Corrugated Cartons

Talk to our experts to customize your corrugation line. Based on your requirements and future expansion plans we can guide you to the best solution. We consider the following points in every project.

Quality Output:

Accurate corrugation, uniform flute , precise cutting, warp-resistant boards.

Cost Efficiency:

Reduced waste, low rejection rates, optimized energy use.

Customizable Setup:

Supports multiple flute types (A, B, C, E, F) and board thicknesses for varied packaging needs.

Applications of Corrugated Paperboard Production

Consumer goods packaging

Master cartons

Food packaging

Repacking

E-commerce packaging

Let’s Help You!

Our team of technical experts is prepared to provide consultation and support

Want to know more?

Download our brochures to explore each product category in detail.

Why Choose AFRA Printechnik for Corrugated Carton Solutions?

Afra Printechnik's corrugated box production line supports board widths up to 2500mm.

Our solutions are available in both manual and fully automated configurations, with options for standalone (offline) or integrated (inline) setups. The line also features automated packing systems and dedicated waste management solutions, ensuring an efficient and seamless end-to-end production process.

If you’re planning to purchase a corrugation production line but aren’t sure where to start, trust Afra printechnik to guide you every step of the way and provide the right solution for your needs.

Corrugated Carton Solution Machines FAQ

What flute types are supported by Afra’s corrugation line?

Our machines support A, B, C, and E,F flute configurations for a variety of packaging applications.

Can the production line handle high-volume output?

Yes, our machines are designed for continuous, high-speed production with minimal downtime.

What materials are compatible with these machines?

Our systems can process various paper grades, including kraft liner, test liner, and recycled board.

How does in-house production compare to outsourcing?

Owning an in-house corrugation line significantly reduces production costs, increases flexibility, and ensures faster turnaround times.

Are your cartons eco-friendly?

Yes, our eco-friendly cartons use recyclable materials and print with water-based inks to reduce environmental impact.