- Home

- Digital Print Finishing

- Thermal Lamination Solutions

Thermal Lamination Solutions

Serious About Print Finishing? Meet Our Thermal Laminators

Built to meet the demands of modern print finishing, Afra Printechnik offers high-performance thermal laminators from Champion and Komfi—perfect for laminating books, brochures, menus, and folding cartons. Engineered for speed and consistent results, these machines protect materials from wear and moisture while enhancing print and packaging quality with finishes like gloss, matte, soft-touch, and more.

Our Solutions

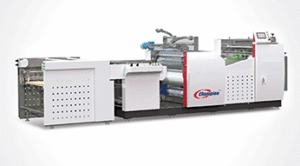

CHAMPION NEOLAM 720

The Champion Neolam 720 Thermal Laminator is engineered for superior print protection and enhancement. Combining speed, consistency, and durability, it delivers a flawless finish across a wide variety of substrates.

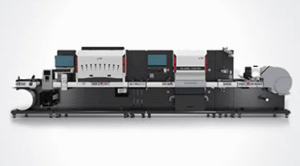

CHAMPION VERSALAM 20SS

VersaLam is a thermal laminator equipped with auto sheet separation and foil glacing, delivering fast and high-quality finishing.

CHAMPION DESKLAM 38C

Compact manual laminator for sheets up to 365 mm — perfect for small jobs, easy operation, and space-saving use.

CHAMPION FOIL-LAM

Foil-Lam is a manual-feed thermal laminator that combines the reliable features of DeskLam with simple foil sleeking, ideal for producing neat, professional finishes

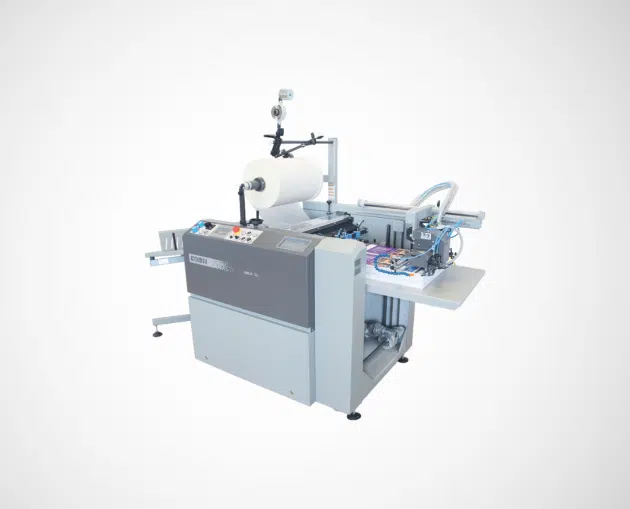

KOMFI AMIGA 36

KOMFI AMIGA 36 high-performance thermal laminating machine that produces smooth, long-lasting finishes with ease and accuracy, perfect for small to medium-sized print projects (36 × 70 cm).

KOMFI AMIGA 52

With its user-friendly design and ability to handle tasks up to 56 × 80 cm, this sheet-fed thermal laminator is ideal for accurate, smooth finishing.

What is Thermal Lamination?

Thermal lamination for book covers, packaging boxes, folders, and other printed paperboard materials uses BOPP, PET, or PVC films with a heat-activated adhesive layer. The laminating machine heats rollers to 100°C–130°C to activate the adhesive, while printed sheets pass through and are coated with the film. Pressure from the heated rollers ensures a smooth, bubble-free finish. This process enhances appearance, adds durability, and provides protection against moisture, scratches, and wear—making it ideal for high-quality print and packaging applications.

Our Range of Advanced Theraml Lamination Solutions

We offer a versatile range of thermal lamination machines to meet diverse needs. The Desklam 38C is a compact and efficient option with a 365 mm width, perfect for everyday use. The Foil-Lam combines lamination with digital foiling, using advanced sleeking technology to apply foil precisely on printed areas for premium effects. The Komfi Amiga handles large-format lamination from 36 × 70 cm to 53 × 80 cm, ideal for commercial applications. For an affordable solution with advanced features, the Versalam 20SS offers a 485 mm width, foil sleeking, and an automatic sheet separator.

Let’s Help You!

Our team of technical experts is prepared to provide consultation and support

Want to know more?

Download our brochures to explore each product category in detail.

Why Choose AFRA Printechnik for Thermal Lamination Machines?

Afra Printechnik, we’ve been helping businesses across the Middle east and Africa for over 27 years with reliable, high-quality thermal lamination machines. Whether you need to laminate business cards, brochures, book covers, or packaging, we offer a wide range of solutions to suit your specific needs. What makes us different? It’s not just the machines — it’s the support behind them. Our experienced team is here to guide you from the start — helping you choose the right model, setting it up, training your staff, and making sure everything runs smoothly long after installation. If you're looking for durable, efficient, and easy-to-use lamination equipment, backed by people who know the industry inside out, Afra Printechnik is your trusted partner.

Thermal Lamination Solutions FAQ

How do I maintain my laminator for long-term use?

- Regularly clean the rollers to prevent film buildup.

- Store the machine in a dust-free environment when not in use.

What are the benefits of lamination machines?

The process delivers a high-quality surface finish with enhanced visual appeal, vibrant colors, and a refined, professional look. It also adds durability and protection, offering improved resistance to water, wear, and handling.

What happens if my substrates gets jammed?

Most laminators have a reverse function to release jammed substrates. If not, turn off the machine, let it cool, and gently remove the film.

How long does a laminator take to warm up?

Most laminators take 30 seconds to 5 minutes to heat up, depending on the model. High-speed industrial laminators have fast warm-up times for increased efficiency.

Can lamination be used for big print finishing jobs?

Machine listed here suites only for digital lamination for large format lamination please check our offset lamination page