- Home

- Offset Print Finishing Solutions

- Thermal Lamination Solutions

Thermal Lamination Solutions

Thermal Laminators: Enhance Your Print Finishing Quality by adding value

Afra Printechnik supplies high-performance thermal laminating machines across the Middle East and Africa, featuring trusted brands like Champion and Komfi. Designed for large-scale production, these systems enhance printed materials such as books, business cards, and tags with premium finishes like gloss, matte, or soft touch, focusing on visual and tactile enhancement to deliver consistent, professional results.

Our Solutions

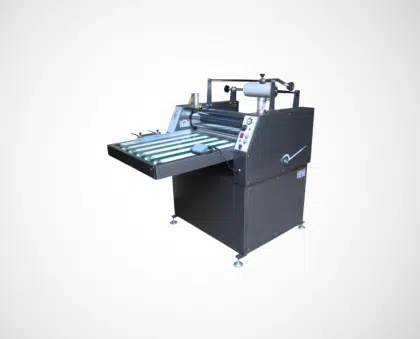

CHAMPION CTL HYD 520/740

Introducing the Champion CTL-HYD 520 Semi-Automatic Thermal Laminator - a high-quality laminating machine that guarantees consistent temperature and pressure which ensures high quality lamination of different substrates.

CHAMPION CTL 680/720/900

Introducing the CHAMPION CTL 680 Thermal Laminator – Your Ultimate Document Protection Solution.

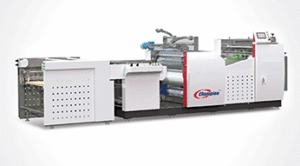

CHAMPION CATL 1100

The Champion CATL 1100 is a state-of-the-art automatic thermal laminating machine designed to deliver precision, efficiency, and durability for high-volume print finishing. Equipped with advanced automation and intelligent controls, it ensures smooth operation, consistent quality, and excellent productivity with minimal operator effort.

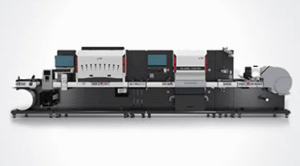

KOMFI SAGITTA 76

Introducing the KOMFI SAGITTA 76 Automatic Thermal Laminating Machine - a robust and durable solution that has been installed and trusted by customers worldwide in 24/7 production environments.

KOMFI AMIGA 76

Introducing the Komfi Amiga 76 Automatic Thermal Laminator - a state-of-the-art hardware and software solution designed and manufactured by Komfi.

CHAMPION AUTOLAM B1

Champion AUTOLAM B1 is a fast, precise automatic thermal laminator with efficient servo-driven feeding and energy-saving heating.

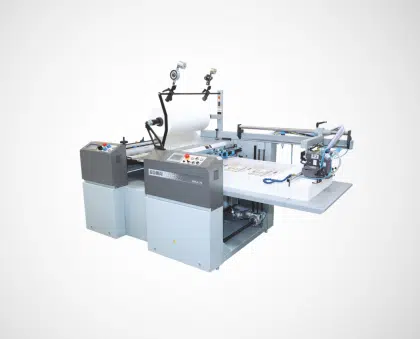

KOMFI DELTA 52

The Komfi Delta 52 is an advanced automatic thermal laminating machine with features for precision and efficiency.

Why Choose Our Thermal Laminators

Thermal laminators not only enhances the durability of your materials but also improves their overall appearance. The process applies a protective layer of plastic to printed surfaces, resulting in vibrant colors, sharper images, and a polished, professional finish. Our thermal laminating machines use advanced technology to ensure flawless results—perfect for marketing materials, brochures, and packaging.

Key Features to Consider in a Thermal Laminating Machines

When selecting a thermal laminator, it’s important to consider several key features that will impact your operations. Speed and efficiency are crucial—choose a machine that matches your production volume to maintain high throughput without sacrificing quality. Versatility is also important; the laminator should handle various film thicknesses and material sizes to accommodate different job types. Additionally, user-friendly controls are essential for simplifying setup and operation, helping to reduce downtime and minimize errors.

Benefits of Thermal Laminating Machines

Thermal lamination offers several valuable benefits. It enhances durability by protecting printed materials from wear and tear, moisture, and UV damage, significantly extending their lifespan. The process also improves the overall appearance, providing either a glossy or matte finish that elevates the visual appeal of any printed item. Additionally, laminated materials are easy to maintain, as they can be wiped clean effortlessly—making them ideal for high-traffic environments and frequent handling.

Let’s Help You!

Our team of technical experts is prepared to provide consultation and support

Want to know more?

Download our brochures to explore each product category in detail.

Featured Thermal Laminating Machines

Featured thermal laminating machines include the Komfi Sagitta 76, a high-speed automatic laminator ideal for large-scale production with quick setup and energy-efficient heating. The Komfi Amiga 76 offers advanced software, touchscreen controls, patented heating technology and waste reduction, perfect for professional digital print lamination. The Komfi Delta 56 is a semi-automatic B2 format machine known for fast setup, precise film alignment, and minimal waste.

The CTL HYD 740 features oil-based heating for stable temperatures and easy one-person operation with manual pressure control. Lastly, the CATL machine provides precise temperature and pressure regulation, durable rollers, and built-in film punching and cutting for smooth, efficient lamination with minimal operator effort.

How to Choose the Right Thermal Laminating Machines

Choosing the right thermal laminator depends on your specific needs. Consider factors like your production volume, the type of finish you want, and the materials you’ll be laminating. Afra Printechnik is ready to help you find the best machine to meet your unique requirements.

Thermal Lamination Solutions FAQ

What materials can be laminated with a thermal laminator?

Thermal laminators can help improve photos and keep important stuff safe. They can also be used to laminate a lot of stuff, like stock with pictures or drawings.

How do I choose the right thermal laminator for my needs?

Consider factors like production volume, desired finish, and material types to select a thermal laminator that meets your specific needs. Our team can assist you with expert guidance.

What heat should I use for lamination?

The suggested temperature for lamination depends on how thick the stuff being laminated is. For example, a 5 mil thick material should be laminated at a temp of 225–240°F.

How do I troubleshoot issues with my thermal laminator?

Common troubleshooting tips include checking film alignment, adjusting speed and temperature settings, and ensuring the machine is clean and free of debris.